Micro Q Inc., San Diego

EQUIPMENT

MicroQ Equipment

With our expertise in SMT Assembly and Chip & Wire Processes, we support customer requirements from the developmental prototype stages to production. We believe our role in the supply chain is to support our customer’s ability to deliver quality product on time, within budget.

FOX2

Components with sizes from 01005 up to 1.3 x 3.1″are placed. The machine achieves 10,800 cph (IPC9850) and still remains 50 µm accuracy, 3 sigma with a two nozzle head. first machine in its class with linear motors and a mineral cast frame, providing excellent speed, stability, accuracy, and making it perfectly suited for use in small to medium production environments.

IConn MEM PLUS BONDER

IConn PLUS is a state-of-the-art, fully automatic ball wire bonder with ± 2.0 μm accuracy. With its upgraded and enhanced subsystems, it is engineered to deliver all the capability you will need – For Wire Bonding today, tomorrow. The IConn PLUS is designed to meet all leading edge wire bonding challenges.

FINCEPLACER

A high level of process modularity allows all rework process steps within one system. The FINEPLACER® pico rs system is at home in R&D, process development, prototyping and production environments.Application area from 01005 up to large BGA on small to medium sized PCBs, with the goal to have highly reproducible soldering results.

Coming Soon

YAMAHA YSM 10-SYS-HM5-SP

Handles a wide range of components from 03015mm (0.3 × 0.15mm) ultra-micro-chips to large parts 55 × 100mm and 15mm in height utilizing high-speed general-purpose heads. World’s fastest mounting speed in its class of 46,000 CPH (chips per hour). Highly stable & reliable pickup system. The YSM-10 is optimized for fast changeovers and complex PCBA’s, with 120 feeder capacity.

PLA TePla Ion 40 Plasma Cleaner

The IoN 40 Plasma System is a barrel plasma reactor designed for R&D and production applications. Plasma Surface Treatment alters the surface of a material in order to improve surface energy, bonding, printing, and wettability. This cleaning process is for wire bonding, and critical assembly processes.

ASSCONN VP510, Vapor Phase Reflow

The VP510 is capable of soldering temperatures of 200 – 260 degrees C for both leaded and lead-free applications defect free. For process reliability, this system offers fully adjustable temperature gradient (TGC); Automatic solder break (ASB) in recognizing the end of the soldering process; Monitoring of all process parameters including fluid and vapor temperature, process fluid recovery with pressure compensation, and automatic fluid measuring to recognize process fluid used.

MPM SPM Screen Printer

The SPM is a very accurate screen printer built for precision batch printing and prototype work. The standard magnetic tooling and PC-based control system allow for quick changeover and maximum flexibility. Also available are several options that will turn the base SPM into an ultra-fine pitch printer with print sizes down to 12 mil pitch, or better.

XZYTEC 70 Condor

Designed for pull and shear test up to 40 kgt. Performing wire pull, ball shear, wedge shear, solder ball shear and shear.

MITUTOYO QUICK SCOPE VISION MEASURING MACHINE

The Quick Scope digital microscope with new optical technology provides industry leading vision measurement accuracy, with high-speed, high-accuracy optical auto-focus for 3D measurements.

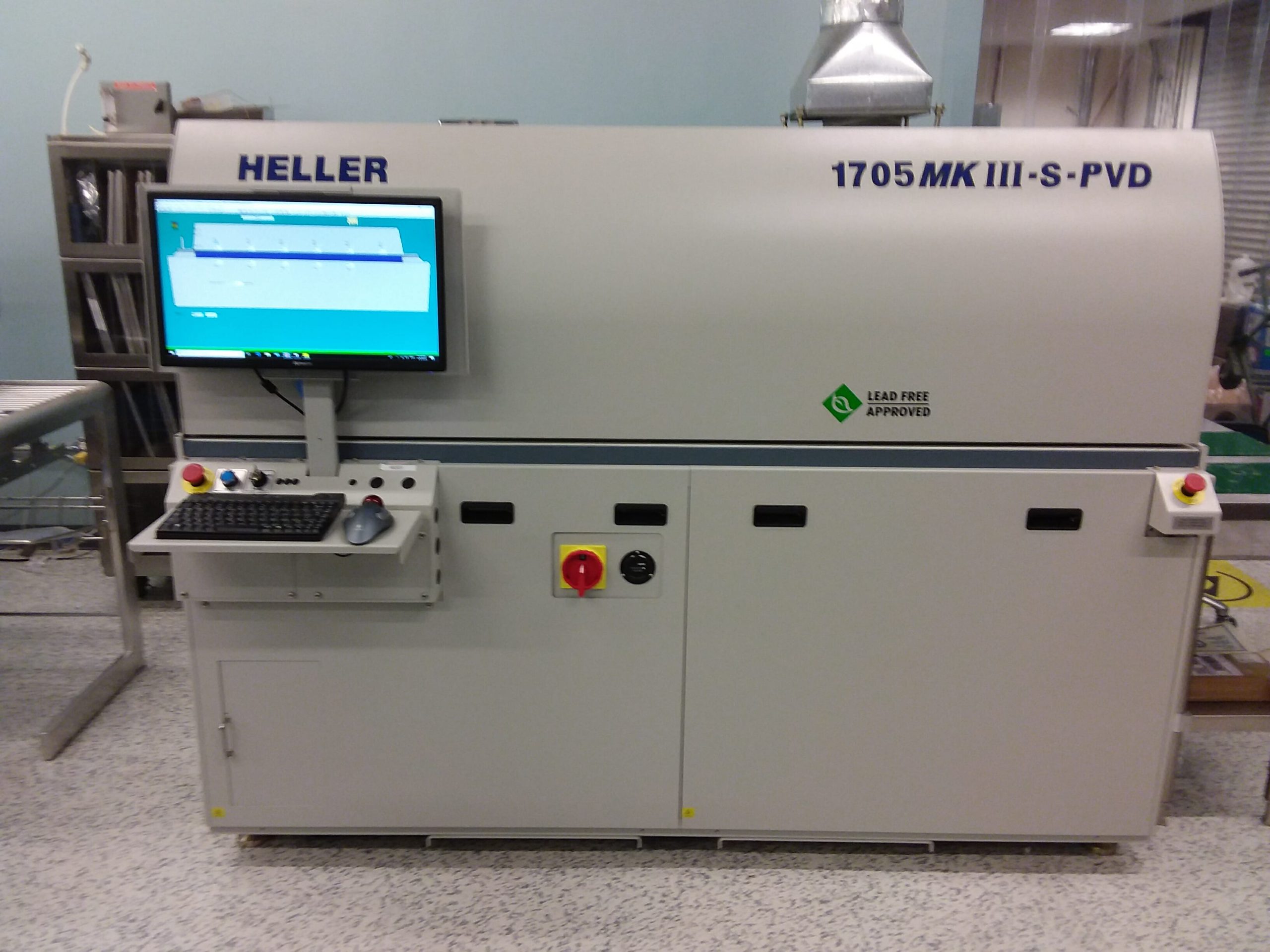

1707 Mark III Series – SMT Reflow Oven

The 1700 models support high mix / medium volume throughput… at speeds up to 24 inches (60 centimeters) per minute. Rapid response times and precise temperature controls assure process uniformity, regardless of component density or board loading, with identical profile performance in either air or nitrogen. The Mark III system includes features 5 heated zones to allow “Profile Sculpting”.

iBond 5000 Wedge Bonders

The iBond5000 manual wedge bonder is for ultrasonic Wedge,Tab, Stitch & Ribbon bonding using aluminium, gold or copper wires.

Unitek Peco Gap Welding

The SPM is a very accurate screen printer built for precision batch printing and prototype work. The standard magnetic tooling and PC-based control system allow for quick changeover and maximum flexibility. Also available are several options that will turn the base SPM into an ultra-fine pitch printer with print sizes down to 12 mil pitch, or better.

Technical Devices AquaBatch XL

The Aqua Batch XL is an efficient batch cleaning system designed to remove all types of electronic assembly residues including water soluble, RMA, no-clean and leadfree soldering fluxes; plating salts, finger soils, dust and loose solder balls. Almost unlimited definable recipes allow selection of either a 100% water-based cleaning process or a chemical/water process with selectable additions of steam cycles or rinse aids to improve the efficiency of the cleaning process.

iBond 5000 Ball Bonder

Designed for pull and shear test up to 40 kgt. Performing wire pull, ball shear, wedge shear, solder ball shear and shear.

AOI systems

For both pre-reflow and post-reflow inspection covering a comprehensive list of component and solder joint defect categories and are fully capable of inspecting 01005 components and beyond. part presence/absence verification, part polarity and pin #1 orientation, part position and skew errors, laser marking, wrong part and device differences such as: labels and colour variations.